|

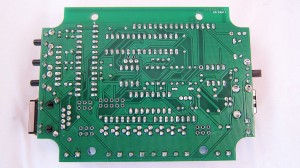

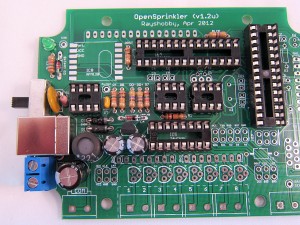

To begin, place the PCB onto a a vise, and turn on the soldering iron. (Optional: use a fume extractor to help remove solder fumes).

Remember: all images on this page are ‘clickable’, in case you want to check full-resolution details.

|

|

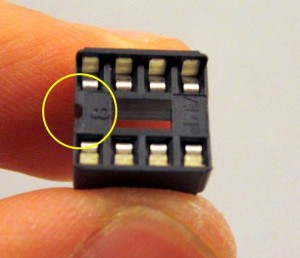

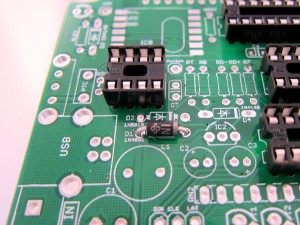

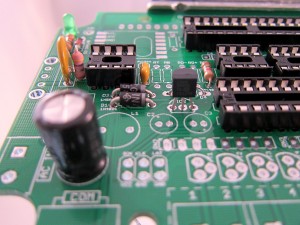

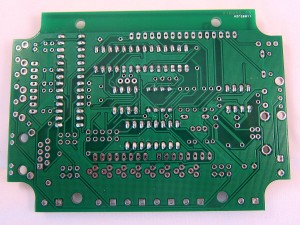

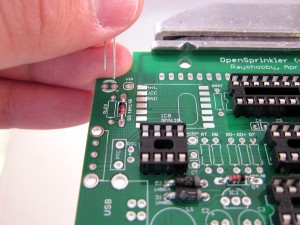

Insert and solder all IC sockets (from the IC bag). Be careful when inserting the IC sockets: make sure all legs go into the PCB holes correctly. You can tape them to the PCB to avoid them falling out during soldering.

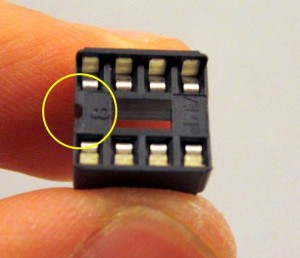

Every socket has a small notch (see the picture on the left) to help identify its orientation. This notch must match up with the silkscreen on the PCB.

|

|

Now we will build the power supply section, the components of which are all located at the left side of the PCB.

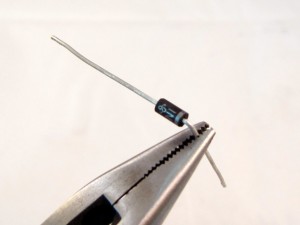

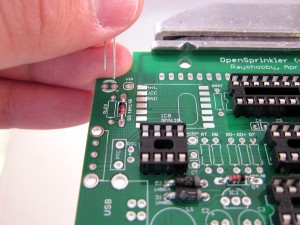

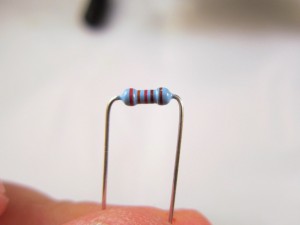

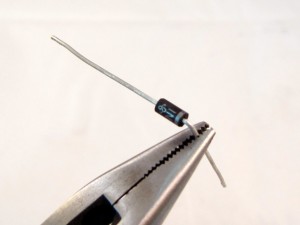

First solder D1, a 1N4001 diode. It looks similar to D2, so be sure to read the label on the diode. Use pliers to gently bend the two legs to 90 degrees. Note that diodes have polarity, allowing current to flow only in one direction. Before inserting it to the PCB, identify the end with a white stripe (the negative leg). This stripe should match the silkscreen on the PCB. Again, when in doubt, click on the images to get a full-resolution view. |

|

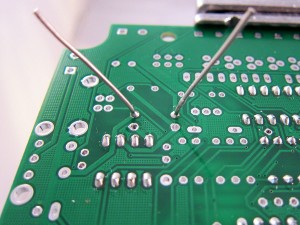

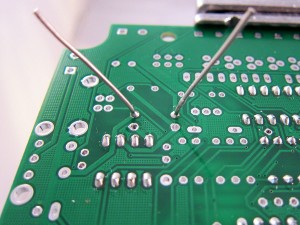

On the back of the PCB, bend the legs to the side, so that you can flip the PCB and the diode will stay in place. Solder both legs.

To make sure the component lies tightly on the PCB, you can solder one leg first, then keep the soldering iron on the joint while pushing or pulling the component towards the PCB. Once it’s in place, proceed to solder the other joint.

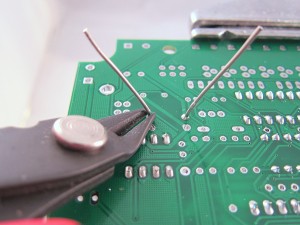

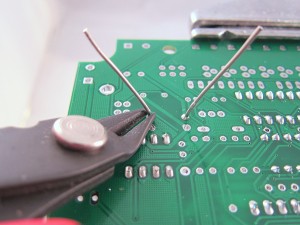

Next, use a diagonal cutter to clip leads just above the end of the solder joints. |

|

Follow the same method to solder D2 — a 1N5819 Schottky diode, as well as D3 and D4 — 1N4148 diode. Again, be careful with the polarity of diodes.

Now solder the green LED. LED is a diode, so it also has polarity. The longer leg of the LED is positive, and should go into the PCB hole marked with + as shown in the photo on the left.

|

|

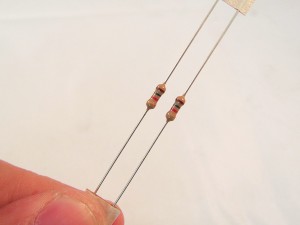

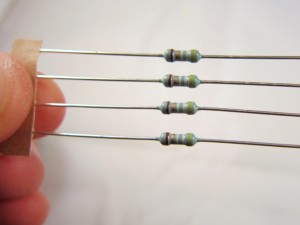

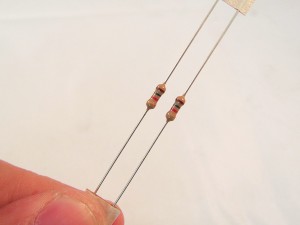

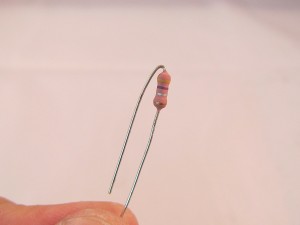

Next, solder RLED, a 1.5K resistor. In the package you will find a strip of two 1.5K resistors. The colored rings on the resistors should read Brown-Green-Red. Resistors are non-polar, so you can insert them either way.

The other 1.5K resistor goes to R7, located above diode D4. This is a pullup resistor for the USB programmer.

|

|

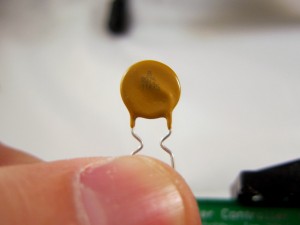

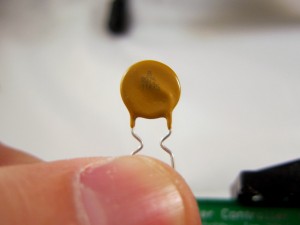

Now solder the PTC fuse. I’s a yellow, disc-shaped component used for current protection. Use plier to straighten the legs a little bit, so it can go into the PCB holes easily.

If you don’t want current protection, you can instead solder a wire across the fuse to disable it.

|

|

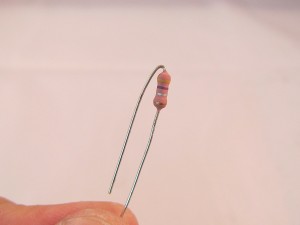

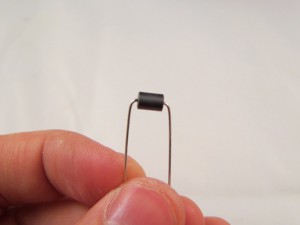

Moving on, now solder RSC, a 0.47 ohm resistor located next to the PTC fuse. The colored rings should read Yellow-Purple-Silver. This resistor needs to be positioned upright, so bend one leg 180 degrees down, insert to the PCB holes, and solder it.

Heads up: during operation, the switching regulator will generate slight audible noise. This is normal. If for some reason the noise is unacceptable, you can replace RSC with a 1 ohm resistor, to limit the output current.

|

|

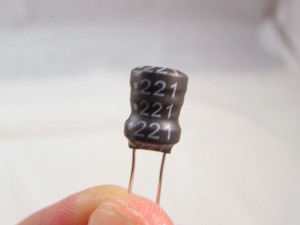

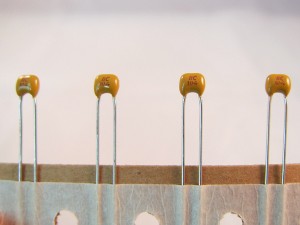

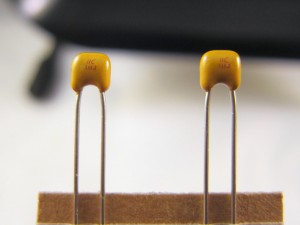

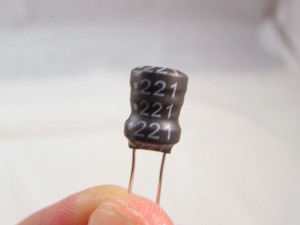

Next, solder CT, a 220pf capacitor. It is a timing capacitor for the switching regulator. This is a small yellow ceramic capacitor, and it comes by itself (i.e. not on a strip). The label should read 221. It is non-polar, so you can insert it any way.

|

|

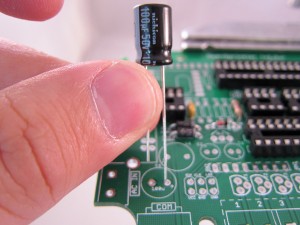

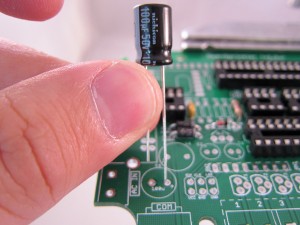

Moving on, now solder C1, a 100uF/50V electrolytic capacitor. It’s a relatively large component. Electrolytic capacitors are polarized, so make sure the longer (positive) leg goes into the hole marked with +. To double check, there is a white stripe on capacitor body which points to the negative leg.

Similarly, solder C2 and C3, two identical 220uF electrolytic capacitors. Again, watch out the polarity and maker longer leg corresponds to + hole.

|

|

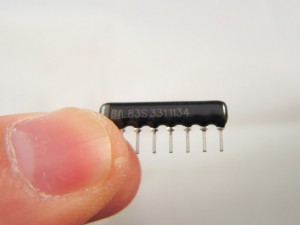

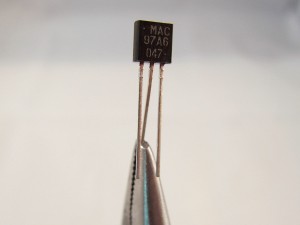

Now solder IC2, an MCP1700-33 linear regulator (from the IC bag). It has 3 pins and is shaped like a half cylinder, similar to transistor. Note: be careful not to confuse it with MAC97, which are triacs from the screw terminal bag.

Align it such that the semi-circle matches the PCB silkscreen. Then solder the three legs at the back of the PCB. |

|

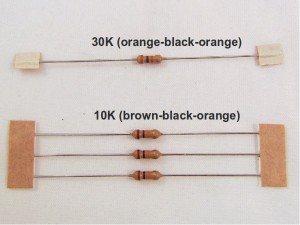

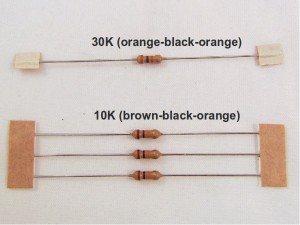

Next, solder RT, a 30K resistor. This looks very similar with the 10K resistors, so be careful. The ring colors should read Orange-Black-Orange (in contrast, the 10K resistors have Brown-Black-Orange colors and come in a strip of three).

The three 10K resistors should go into RRST, RB (close to the switching regolator), and R1 (located right above the 74HC595 shift register. So solder them as well.

|

|

Next, solder L1, a 220uH inductor. The label should read 221.

Note: more recent packages are shipped with a 270uH inductor, the label of which is 271. |

|

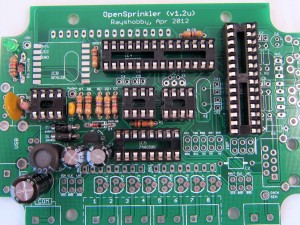

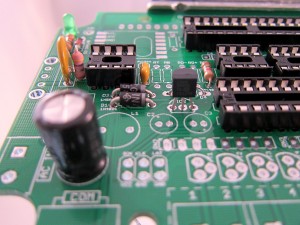

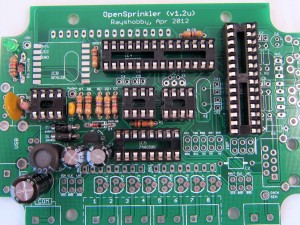

Now you can solder RLCD, RD+ and RD-. These are three 47 ohm resistors that come in a strip of three. The color rings should read Yellow-Purple-Brown.

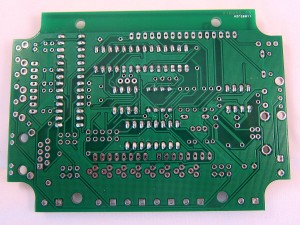

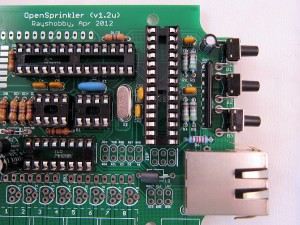

After you are done with this step, check your PCB against the image on the left. Click the image to get a high resolution view.

|

|

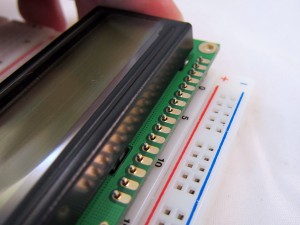

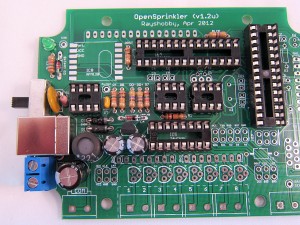

Now solder the Slide Switch, the USB connector, and the power supply Screw Terminal on the left edge of the PCB. Check the image on the left.

The slide switch and USB connector will touch with each other. This OK, no worry about it.

|

|

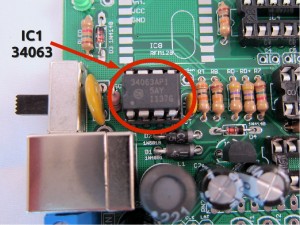

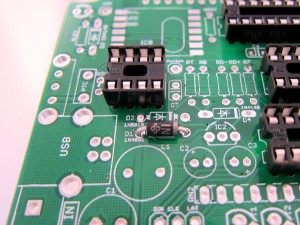

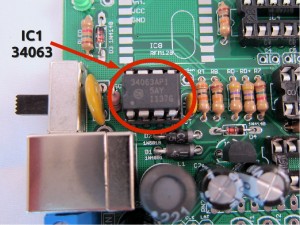

We are almost done with this part. Insert IC1 into its socket. This is a MC34063 switching regulator, which is used to step the input voltage down to +5VDC. Make sure that its notch matches the notch on the socket. Refer to the picture on the left.

Double check that you have inserted MC34063, not the other two ICs (24LC128 and ATtiny45) which are also in 8-pin package.

|

|

Now it’s time to test the power supply section. First, slide up the power switch to turn it off. Then, insert the two wires on your 24VAC sprinkler transformer to the screw terminal on the left. After you have tightened the screws, slide down the power switch, and you should see the green LED lit.

Important: (although this is unlikely) if anything burns or smokes, immediately turn off power. Check to see if there is any component visibly damaged. If you can’t figure out the problem, post a message in the forum and we will help you.

During operation you will hear a slight audible noise due to the switching frequency of the regulator. This is normal. If the noise is unacceptable replace the 0.47 ohm resistor with a 1 ohm resistor, but keep in mind that this will limit the output current.

|

|

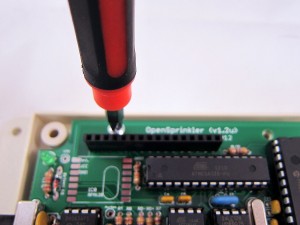

Voltage check: use a multimeter, measure the voltage between GND and VIN (located at the upper-left corner of the PCB). It should read about +5V. This is the voltage supplied to the LCD.

Next, measure the voltage between GND and VCC, it should be around +3.3V. This is the voltage supplied to the rest of the circuit.

Important: It’s crucial to check and ensure these voltage readings are correct, otherwise your controller may not function properly.

After testing the voltages, disconnect the power.

|