|

To begin, place the PCB onto a a vise, and turn on the soldering iron. (Optional: use a fume extractor to help remove solder fumes).

Remember: all images are ‘clickable’.

|

|

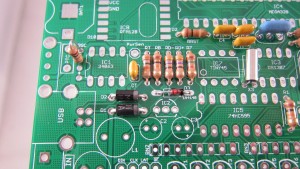

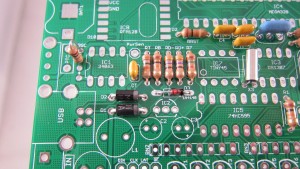

Start with the four 49.9 ohm resistors (taped together) and five 0.1uF ceramic capacitors (on a strip). These correspond to R2, R3, R4, R5 and C4, C5, CR, C7, C8. Click the image on the left to see where they are located on the PCB. These components are non-polar, so it doesn’t matter which direction you insert them.

To solder a resistor, bend its two leads as close as possible to the resistor body, then insert it to the PCB holes. To increase productivity, I usually insert multiple components at once, and use painter’s tape to fix them in place (see image on the left). You can use as many pieces of tapes as you need. Then flip the PCB and solder all leads. This way you can reduce the total number of times to flip the PCB. However, avoid inserting too many components such that the back of the PCB will be too crowded to get your soldering iron around.

After soldering, use a diagonal cutter to clip the leads just above the end of the solder joints.

|

|

(Oct 2012 PCB Update: X1 has been removed as the mcu is now programmed to use internal clock).

Next, solder three two crystal oscillators: X1 (8MHz, blue colored, three pins), X2 (25MHz, oval, two pins), and X3 (32.768KHz, small cylinder shaped, two pins). Click the image on the left to see where they are located. These components are non-polar.

Solder three ceramic capacitors: CT (220pF), CX1 and CX2 (18pF, on a strip of two or taped together). These three capacitors look very similar, but using a magnifying glass, you will see that CT is labeled 221, while the other two are labeled 180.

Also solder L2, a ferrite bead. It’s cylinder shaped, and non-polar.

|

|

Now you will solder a bunch of resistors. They are listed below:

- RB, RRST, R1, RCL, RDA: five 10K resistors. Ring colors: Brown-Black-Orange. These come on a strip.

- R8, R9: two 1K resistors. Ring colors: Brown-Black-Red. These two resistors come together on a strip.

- RD+, RD-: two 47 ohm resistors. Ring colors: Yellow-Violet-Black. Again, they come together on a strip.

- R6: 2.32K. Ring colors: Red-Orange-Red.

- RT: 30K. Ring colors: Orange-Black-Orange.

- R7: 1.5K. Ring colors: Brown-Green-Red.

Click the image on the left to see where they are located.

|

|

Next, solder Rsc, a 1 ohm resistor located on the left side of the PCB. The kit contains a strip of two 1 ohm resistors. The ring colors are Brown-Black-Gold. This is a current limiting resistor. It needs to be positioned upright. So bend one lead 180 degrees down, and solder it.

(Oct 2012 PCB Update: this is an optional step: if you want to power a WiFi adapter through OpenSprinkler’s USB port, solder the second 1 ohm resistor to the two holes below Rsc. This helps increase the current output of the +5V line). |

|

(Oct 2012 PCB Update: solder RLED, a 100 ohm resistor located at the top of the PCB.)

The other 1 ohm resistor goes to RLED, located at the top of the PCB.

Above RLED is D4. It’s marked as a diode but is now replaced by a 100 ohm resistor. The ring colors are Brown-Black-Brown. So ignore the PCB silkscreen and solder the 100 ohm resistor here.

|

|

(Oct 2012 PCB Update: D1 is now replaced by a R3000 diode.)

Now solder three diodes: D1 (1N4001), D2 (1N5819), and D3 (1N4148). They are all located on the right of the USB connector.

To solder a diode, use pliers to gently bend the two leads to 90 degrees. Important: diodes have polarity, allowing current to flow only in one direction. Identify the end with a white stripe (the negative lead). This stripe should match the silkscreen on the PCB. Compare yours with the image on the left.

|

|

Next, solder IC2, an MCP1700-33 linear regulator from the IC bag. It has 3 pins and is shaped like a half cylinder, similar to a transistor. Note: be careful not to confuse it with the triacs from the screw terminal bag. Align it such that the semi-circle matches the PCB silkscreen. Then solder the three leads at the back of the PCB.

|

|

Next, solder L1, a 220uH (or 270uH) inductor. The label should read 221 (or 271). Inductors are non-polar.

Moving on, now solder C1, a 100uF electrolytic capacitor. Its a relatively large component. Electrolytic capacitors are polarized: make sure the longer (positive) lead goes into the hole marked with +. To double check, there is a white stripe on capacitor body which points to the negative lead.

|

|

Similarly, solder C2 and C3, two identical 220uF electrolytic capacitors. They look similar to a 10uF capacitor that you will solder next. So please read the label on each capacitor to tell them apart. Again, pay attention to the polarity and remember the longer lead goes into to + hole. Don’t take things for granted: especially note that C2 and C3 have opposing positions on the PCB. Compare yours with the image on the left.

Now solder C6, a 10uF electrolytic capacitor located at the upper right corner of the PCB.

|

|

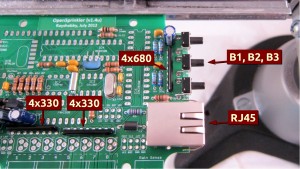

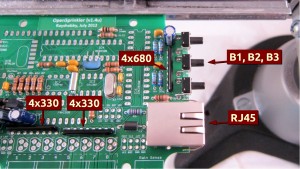

In the next step, solder three resistor arrays: RN1 (one 470 ohm, or depending on your package, it may be 680 or 220), RN2 and RN3 (two 330 ohm). Each resistor array has eight pins and consists of four identical isolated resistors. It is symmetric so you can insert it in any direction. You can identify the resistor array by reading its label. For example, 470 ohm resistor array should have ‘471’ in its label, 220 ohm array should read ‘221’, and 330 ohm array should read ‘331’.

After you are done with the resistor arrays, solder three right-angle pushbuttons: B1, B2, B3, as well as the RJ45 Ethernet connector. These are located on the right edge of the PCB. When inserting the RJ45 connector, be careful not to bend the pins.

|

|

Now move to the left side of the PCB, and solder the USB connector, as well as the PTC fuse. The PTC fuse is a yellow disc-shaped component. Use pliers to straighten the legs, then insert it to the PCB holes.

|

|

Next, solder the slide switch.

|

|

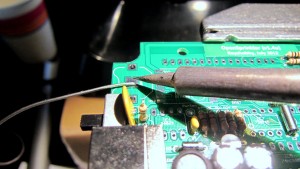

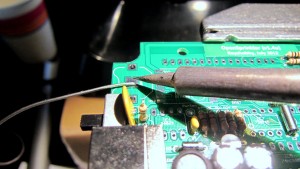

Now solder the coin battery holder. To begin, use a small amount of solder to tin the PCB pad. This is important to ensure the battery has good contact with the pad.

The image on the left shows the result of tinning. It should be a very thin layer.

Now go ahead and solder the battery holder.

|

|

Next, solder the 2×4 Extension Board Connector, located below L2.

|

|

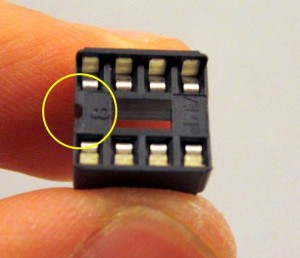

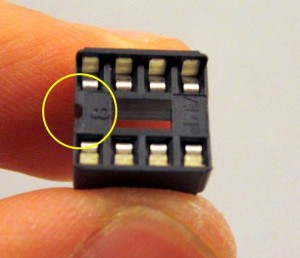

Solder all IC sockets (from the IC bag). Be careful when inserting the IC sockets: make sure all socket pins go into the PCB holes correctly, and no pin is left out.

Every socket has a small notch (see the picture on the left) to help identify the orientation. This notch should match up with the silkscreen on the PCB.

|

|

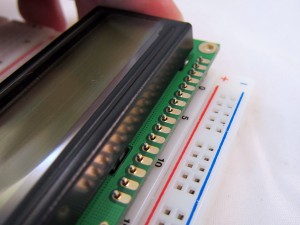

Next, solder the 1×16 female pin header for the LCD. This pin header is located at the top of the PCB.

|

|

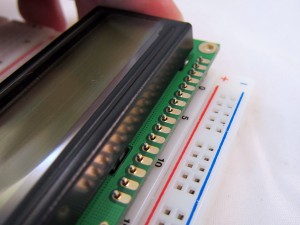

Now take out the LCD and the 1×16 male header. Solder the male header onto the LCD. The easiest way to do so is by making use of a breadboard to hold the pin header during soldering. |

|

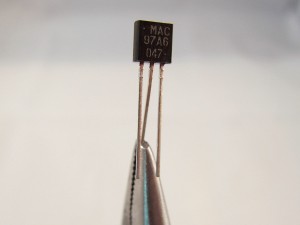

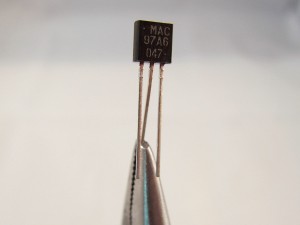

Next, solder the eight triacs (MAC97) T1-T8. Use your hand to bend the middle pin slightly backward, so that you can easily insert it to the PCB holes. Watch out the orientation of the triac.

|

|

The last step of soldering is the screw terminals. Take them out from the screw terminal bag. Solder the AC In, COM, station terminals S1-S8, and the Rain Sensor terminal. Note that each terminal consists of two pieces. You can solder the board piece (with right-angle pins) first, then plug in the terminal piece.

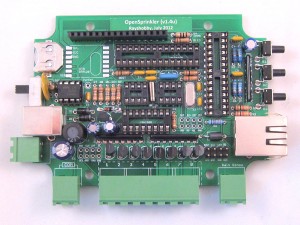

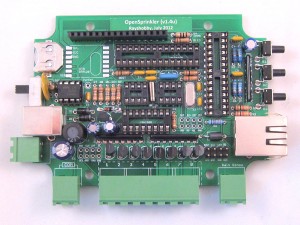

Now you are all set with the soldering part! Check your circuit board with the image on the left.

|