I’ve made a minor update to OpenSprinkler Pi (OSPi), and the new version v1.02 has improved design of the separation pillars in order to make use of the screw holes available on Raspberry Pi rev. 2. See the picture below:

This way, the Raspberry Pi rev. 2 can be more securely attached to the OSPi even with just two screws.

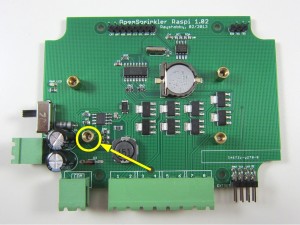

If you own a Raspberry Pi rev. 1 instead, don’t worry, you can still attach it to OSPi using the two edge screws (see the picture on the right below), in the same way as the original OSPi. To do so, you will need to move one of the separation pillars. See the picture on the left below (sorry, the arrow is pointing in the reverse direction).

So in sum, the updated version OSPi v1.02 allows you to make better use of the screws holes available on RPi rev. 2 while still being compatible with RPi rev. 1.

Tags: arduino, raspberry pi, sprinkler solenoid