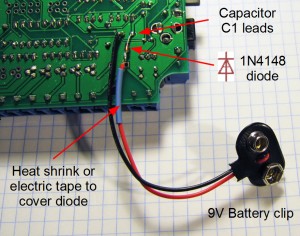

Matt asked about the option of having a backup battery for the OpenSprinkler, so I prepared a short blog article to show how it can be done. Basically, you just need to get a 9V battery (or any battery that can provide 6V or above voltage), connect the positive lead with a diode (such as 1N4148) in forward direction to the positive lead of C1 (100uF capacitor), and the batterys negative lead to C1’s negative lead (which is ground). See pictures below for illustration. Make sure to use a heat shrink or electric tape to cover the diode after it’s soldered.

With the backup battery, the microcontroller (and hence the time) will keep running when there is power outage. Once the main power is back on and the Ethernet connection is available, the controller will be able to obtain more accurate time through NTP sync (the default setting is one sync per hour).

But there is a catch (as always!), which is: the controller draws a lot of current (~140mA), so with a standard 9V battery (the typical capacity of which is 560mAh) it can only last for about 4 hours.

The large current draw is mainly due to the Ethernet controller. One solution is to use a higher capacity battery (such as AA or Li-Poly). Another option is to put the Ethernet controller to sleep when it cannot get a connection. This can be done in software. In any case, there is now a temporary solution for battery backup, and a better option will be provided in the next hardware update.