It’s hard to believe that two years have gone by since my last post. Lots of things happened during these two years: on the good side, we have our first baby born during a year of pandemic, and he is bringing joy to the family every day. On the bad side, there is a pandemic, which brought so many challenges, from supply chain issues to shipping delays and to the difficulty of finding available employees to hire. The pandemic has also taken a huge roll on my mental health, significantly limiting my productivity and creativity.

This post is my attempt to resume regular blogging, a habit that I’ve always enjoyed in the past but was lost during the two terrible years. I am hoping this will motivate me to continue learning and sharing new knowledge about electronics, and continue to provide new passion in my life.

In this post, I will briefly summarize I/O expander choices I’ve considered when designing the OpenSprinkler circuits, and the pros and cons of each choice. I/O expanders are often necessary when the microcontroller’s I/O pins are insufficient for the application. For example, a sprinkler controller may need a large number of output pins in order to drive many zones independently. This is the reason that from the very first version of OpenSprinkler, I’ve decided to use an output expander, to allows the number of zones to be scalable and not limited by the available I/O pins on the microcontroller itself.

74HC595 Shift Register

The most common choice for increasing output pins is to use a 74HC595 shift register, or more precisely: serial-in, parallel-out shift register. 74HC595 is cheap, widely available, and quite simple to connect to a microcontroller like Arduino. Each chip adds 8 output pins, and you can daisy chain them to almost any number, limited only by the potential signal degradation/distortion when cascading too many of them. At the minimum, a microcontroller only needs to use 3 pins to interface with any number of daisy chained shift registers. These pins are named LATCH, CLOCK, and DATA, which are essentially CS, CLOCK, and MOSI pins in SPI terms. You can begin the data transfer by setting LATCH pin low, then at the rising edge of each CLOCK cycle, the HIGH or LOW signal presented on the DATA pin is transferred to the first storage register, while the data already transferred in previous clock cycles are shifted down to the next storage registers respectively, hence the name ‘shift register’. After 8 clock cycles, 8 bits of data are shifted in. Finally set the LATCH pin high, upon which the values in the storage registers are transferred and presented on the output buffers. You can bit bang the pin values, use Arduino’s built-in shiftOut function, or if CLOCK and DATA pins happen to be connected to the microcontroller’s SPI CLK and MOSI pins, you can use SPI functions for even faster operation.

One advantage of 74HC595 is that it has a separate set of storage registers vs. output latches (aka output buffers). During data transfer, this allows the output values remain stable and not affected by the data that’s being shifted in. The output values only update upon the rising edge of the LATCH pin. This compares favorably to other shift registers like 74HC164 that are even cheaper but don’t have output latches (thus the output values may flicker during data transfer and such the flickering would be problematic for output devices like sprinkler solenoids).

Pros:

- Very cheap (a couple of cents in bulk pricing) and widely available.

- Can be daisy chained to enable a large number of output pins

- Relatively small number of microcontroller pins required to interface with it.

While the list of pros makes it sound like this is the perfect choice for almost any application, there are also a number of cons which are somewhat subtle but important for sprinkler controllers.

Cons:

- 74HC595 is output only, it does not support input pins (for that there are dedicated parallel-in, serial out shift registers, basically the opposite of 74HC595).

- Maximum output current is small — according to the datasheet, each output pin can only source or sink up to 4~7mA, depending on the supply voltage. If the output device is a transistor or MOSFET, this is more than sufficient. But on AC-powered OpenSprinkler, the output device is a traic, such as MAC97 or Z0103MN, which require relatively large gate current, and 4~7mA is only barely enough.

- Upon powering up, the output states are not deterministic — this means if LEDs are connected as output devices, they may have a brief moment of flickering upon powering up; similarly if the output devices are solenoid drivers like traics, some solenoids may be momentarily activated until the microcontroller clears out the output buffer. This problem can be alleviated by using an additional pin — the output enable pin — to disable the output latches upon powering up, but the downside is this requires another microcontroller pin.

- The communication between microcontroller and shift register is one-way, so it’s difficult for the microcontroller to detect or enumerate how many shift registers are connected. On OpenSprinkler, I had to use an analog pin in conjunction with a parallel resistor per shift register to be able to detect/enumerate the number of shift registers. This is a downside, particularly if the microcontroller is short of analog pins.

I2C I/O Expanders (such as PCF8574/8575/PCA9555/9535)

Due to the advantages of 74HC595, I used it on the legacy versions of OpenSprinkler (1.x and 2.x) for many years, until I had to move on to switch the microcontroller to ESP8266, in order to support built-in WiFi. Suddenly the cons of 74HC595 became a show stopper, partly because ESP8266 has a much smaller number of GPIO pins, so I could not afford to spare many GPIO pins to interface with 74HC595; and partly because ESP8266 has only one analog pin, which has to be used for solenoid current sensing, thus cannot be used to detect/enumerate the number of expanders.

This is where I discovered there are a large family of I2C I/O expanders. In fact NXP has a document that nicely summarizes the various choices. Most of them differ by the number of I/O pins available, output type, maximum output current, the availability of pull-up resistors on each pin. The output type is quite interesting: some of them use push-pull (i.e. Totem-poll) which means they can both source and sink a large amount of current (i.e. strong current sources and sinks); some of them (e.g. Quasi-output) can sink a large amount of current but only source a small amount of current (i.e. strong sinks but weak sources); some of them (e.g. open-drain) can only sink current but not source current at all.

Most of the pros and cons below are exactly the counterparts of the cons and pros of 74HC595 respectively.

Pros:

- Each pin can be configured as either input or output, so with a single I/O expander chip, some of the pins can be configured as outputs to drive triacs or MOSFETs; while others can be configured as inputs to read sensor values or button statues.

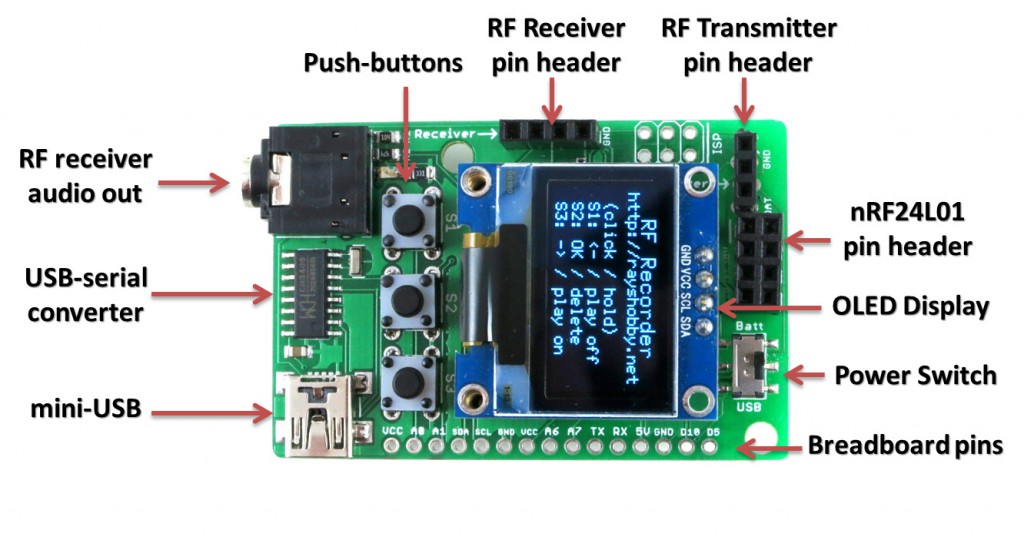

- All of them interface with the microcontroller through I2C, therefore they require only the SDA and SCL pins from the microcontroller, and the same two pins can be shared with other I2C devices such as real-time clock, OLED display etc. This is particularly suitable for ESP8266, on which the number of GPIO pins are very limited.

- Using I2C almost means the communication is bidirectional — the microcontroller can detect and enumerate the number of I/O expanders connected to it.

- Another advantage of I2C is that each I/O expander has a unique I2C address, so by carefully allocating the address of each expander, the microcontroller can detect which type of OpenSprinkler (AC-powered, DC-powered, or Latch) by reading the I2C address.

- The I/O pins on these expanders can source or sink a large amount of current (up to 25mA), which is more than sufficient to drive triacs. Well, not all of them though: when designing OpenSprinkler 3.0, I was only aware of PCF8574 and PCF8575, which are weak current sources, so they have to be combined with PNP transistors or P-ch MOSFETs to source a large number of current. By the time I started designing OpenSprinkler 3.1 and 3.2, I became aware of PCA9555 and PCA9535 — they are strong current sources so there is no longer need for additional transistors or MOSFETs.

- Upon powering up, the output states are deterministic — in fact, the outputs are always high upon powering up, with weak pull-up resistors. This makes it possible to overcome the flickering issue at powering up.

Cons:

- They are relatively expansive (a dollar or so in bulk pricing). While this may not seem much, it does stand out quite significantly when compared to the pricing of 74HC595. Also, the chip shortage caused by the pandemic has made them even more expensive and frequently out of stock. In contrast, it hasn’t affected the pricing or availability of 74HC595 much.

- Because each expander must have a unique I2C address, and each chip (e.g. PCA9555) only has 3 bits of address pins, this means you can only connect up to 8 expanders chips. This is also a disadvantage compared to 74HC595 where you can daisy chain virtually unlimited number of expanders. Despite this limitation, I decided this is a worthwhile compromise to make for OpenSprinkler as the total number of zones per controller is usually not that much.

Among all the I2C expander chips, PCF8574/8575/PCA9555/9535 are relatively more common and available. The differences between them are:

- PCF8574 has 8 I/O pins, and PCF8575 has 16. Both of them are of Quasi-output type, so they can sink but not source a large amount of current. They were used for OpenSprinkler 3.0 controller and zone expanders.

- PCA9555 and PCA9535 both have 16 I/O pins, and both use Totem-poll output, so they can both sink and source a large amount of current. They are used in the current OpenSprinkler 3.2 controller and zone expanders. The only difference between the two is that PCA9555 has built-in pull-up resistor while PCA9535 does not. Thus for any pin configured as input, PCA9535 requires an external pull-up resistor.

CH423s I2C I/O expander

Recently I discovered a very low-cost I2C I/O expander CH423s. It’s made by a Chinese company QinHeng which is famous for making the low-cost USB-serial chip CH340. CH423s has a bulk pricing of about 20 cents, and it has 16 output only pins with 8 additional input/output pins. So it’s a quite capable and versatile chip. However, after reading its datasheet and understanding the sample programs, I found it has a big downside, that is it takes over too many I2C addresses. This is a quite strange design of the chip — unlike PCA9555/PCA9535 (each of which only takes over one I2C address, and you can configure the input/output of each pin by settings configuration registers), CH423s uses multiple I2C addresses to eliminate the need of configuration registers. While it is relatively easy to program, the large span of I2C address space makes it infeasible when the same I2C bus has to be shared with other devices like real-time clock and OLED display, which may conflict with its address space. Also, there are not configuration bits for the I2C address, so it’s not possible to use it on zone expanders. Nonetheless, this is an interesting choice to consider for some applications, if the I2C address space is not a problem.

1-Wire I/O expanders (DS2413/DS2408)

Wouldn’t it be nice if the microcontroller only needs one-pin to communicate with I/O expanders? It turns out such an option does exist! Take a look at the 1-Wire I/O expander chips: DS2413 supports two I/O pins, and DS2408 supports 8 I/O pins. They interface with a microcontroller through a single data wire, hence the name 1-wire. Probably the most well-known 1-wire device is the DS18B20 temperature sensor. While this may not seem a lot of I/O pins, each chip actually has a globally unique address, so you can connect virtually unlimited number of these chips, all sharing a single data line! These chips were brought to my attention by Patrick Morse — he proposed this as a solution to implement Hunter’s EZ Decode system. In fact, before his email, I’ve from time to time received requests to develop a 2-wire decoder system — similar to I2C, 2-wire decoders use a clock line and data line to transfer signals between the microcontroller and the solenoid driver. This is an attractive solution for applications where it’s a hassle to install a large number of long copper wires between the sprinkler controller and each solenoid. 2-wire decoders solve the problem by connecting all solenoid serially using only 2 data lines. Each decoder would have a unique address just like in the case of I2C. The microcontroller sends commands to discover the unique address of each decoder connected on the bus, and consequently can switch each solenoid valve independently. The 1-wire decoder would be a further simplification by reducing one data wire. The commercially available 2-wire decoders generally use proprietary communication protocols that are not open-sourced. The existence of DS2413 and DS2408 means we can easily implement a 1-wire decoder using well-documented 1-wire protocol. That’s great!

Pros:

- Using one single data line, suitable for implementing 1-wire decoders that can significantly save the amount of copper wires required in a sprinkler system.

- Each chip has a globally unique 1-wire address, making it possible to connect a large number of chips all sharing the same data line. By detecting the 1-wire address, the microcontroller can detect and enumerate each chip.

Cons:

- Relatively expensive: DS2413 has a bulk pricing of close to 2 dollars, and it only supports 2 I/O pins. Also they are less commonly used so more prone to chip shortage issues.

While it’s possible to interface with these devices by directly using a microcontroller pin (through the open-source 1-wire library), it may be better to use a 1-wire master chip, which interface with the microcontroller through I2C and it can talk to 1-wire devices using a more robust data line. The 1-wire master chip is particularly useful for ESP8266, which doesn’t have many GPIOs, so it may be necessary to delegate the communication task to a separate chip.

To conclude, this posts summarizes some of the I/O expander options I’ve considered when designing OpenSprinkler circuits, and the pros and cons of each. In the case of OpenSprinkler 3.x, the design decisions were largely driven by the limited number of pins on ESP8266. With other microcontrollers that are not short of GPIO pins, 74HC595 may still be the most attractive choice due to its many advantages and the significantly lower cost.